When choosing the light poles for your project, there are several factors to take into account. This guide to commercial-grade light poles will help you make an informed choice according to your needs. In it, we will explore the following:

- The type of light pole that you’ll need.

- The geographical considerations.

- The type of material that the light pole is constructed of.

- The size of the light pole.

- The installation method of the light pole.

- The amount of light needed from the associated light fixtures that you’ll be using.

What Kind of Light Pole Do I Need?

First, consider the kind of pole you need. Why do you need it, and what purpose will the light pole and the light emitting from it serve? What is the size of the space, and how much light will you need? Are you looking for a decorative light pole? Will you need indoor pole lights or outdoor pole lights? Here are some of the most common purposes for light poles and the questions you should be asking:

- Sporting: What is the size of the venue you are lighting? Also, is it for professional sports or amateur? Is there a television broadcast involved, or are you simply lighting for the spectators at the venue? And how will the athletes and spectators be impacted by the lighting?

- Parking Lot: What is your parking lot’s size, and what is the traffic volume at night? If there are very few cars at night, you might not need the brightest lighting.

- Outdoor Area Lighting: What is the purpose of the area you are lighting? Is it a commercial use area that needs to be brightly lit? Or is it an area with very little pedestrian traffic like the side of a building that might not need the same lighting considerations as a heavily trafficked area?

- Transportation: Highways and residential streets require different light levels for safe traveling conditions. For example, interstates require higher light levels due to larger traffic density while residential streets do not require as much light.

Where will the poles be located?

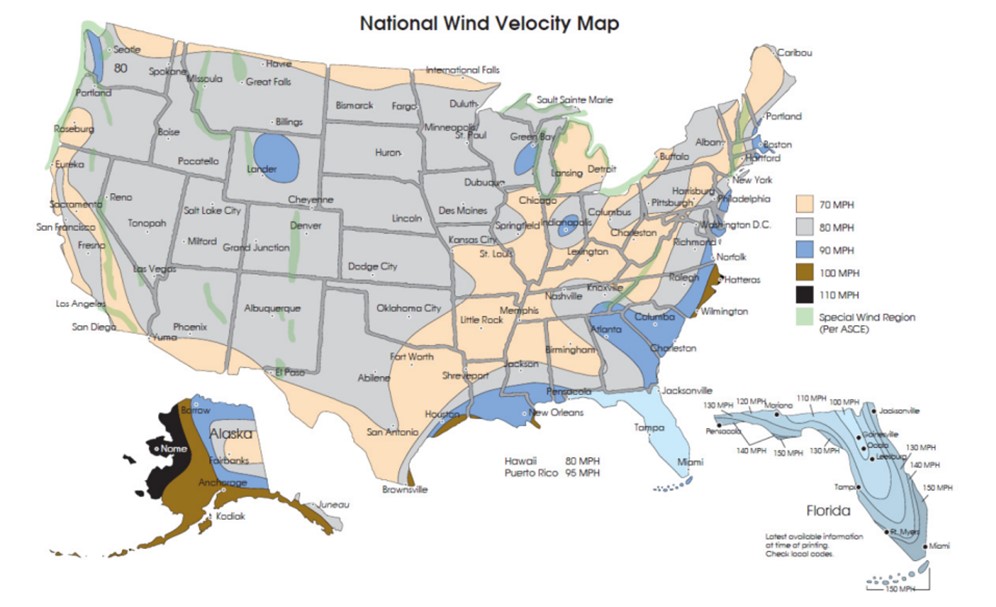

The location of outdoor pole lights is essential since you must consider the space’s lighting needs, the effects of weather on the pole material, and the pole’s structural integrity. How strong do the winds in the area get is the biggest question. The figure below (National Wind Velocity Map) shows a typical wind map of the United States with maximum wind estimates. Use the following map when selecting poles suited for your region and how much weight you are putting on top of the pole.

For more information, see our article on EPA ratings.

The outdoor pole lights will be exposed to the elements for their entire lifespan, so the material choice is critical. A dry climate with little moisture will require a different material than poles located in a coastal area where frequent rain contributes to the humidity in the air.

Also, the closer the poles are located to the coast, the more susceptible they will be to saltwater corrosion. This could lead to rusting that can seriously damage the pole, contribute to a negative cosmetic appearance, and even compromise the pole’s structural integrity. This factor will significantly affect the material you choose for the pole.

Need help with your next lighting project? Contact LightMart today!

What material is needed?

It’s essential to consider the material of the light poles. Your choice will determine the pole’s appearance, durability, and lifespan. Here is a rundown of the available materials and how they match up.

- Wood: inexpensive but not as visually appealing as other materials. Since the wood is solid, the electrical wiring must be attached to the outside. Outside wiring has to be weatherproofed to meet electrical codes.

- Fiberglass: a more expensive option as well as a lightweight material. While it is resistant to water, it is not as sturdy as other material options.

- Aluminum: reasonably priced with a good appearance. The material is lightweight, provides good protection from the corrosive effects of weather, and has a long lifespan. As a disadvantage, aluminum has limited mounting heights and is not as strong and durable as steel. Due to their lightweight, aluminum poles are also easier to install since they may not require equipment to erect.

- Steel: the most popular material choice because of its strength, lifespan, and reasonable prices. On the downside, steel will rust and corrode, which means high maintenance costs along with the labor involved.

- Concrete: it has a long-life span, is an extremely strong material, does not corrode or rust, and does not require much maintenance. However, concrete poles are difficult to install and transport, they are not visually appealing, and they are expensive.

What size/height of pole do you need?

Light poles vary in height by 20-70 feet based on the purpose of the lighting and the area to be lit. Typical heights for street light poles are about 20 feet, while light poles for sports venues may be as high as 70 feet. Consider the size of space you are lighting since it will impact the height of the poles, and lighting efficiency will come into play.

In general, the height of the pole impacts how far the light is dispersed. For smaller areas, like a small parking lot, your light poles could be at the height of 20 feet. However, for bigger spaces that need more light coverage, like a highway, light poles may have to be 30-40 feet in height to adequately cover all areas.

Light source output is another factor to consider in pole height. For larger areas, fixtures emit higher amounts of light, so the pole should be taller. This will give uniform coverage of the area and cut down on glare. Conversely, you will most likely use a fixture that emits lower light for smaller areas, so the pole height will be shorter. Also, if you mount a pole with a low light-emitting fixture too high, it will not light the area effectively.

Installation Methods: Anchor-Based vs. Direct Burial

There are two methods when installing light poles: anchor-based and direct burial. Both are useful and have pros and cons.

- Anchor-based: Poles are attached with base plate and anchor bolts to the ground. A concrete footing is poured, and the anchor bolts are cast into the mold. The area that emerges above the surface becomes the light pole’s base. While anchor-based installation is more costly and time-consuming, it is a good choice for areas where the poles may be frequently damaged, such as a parking lot. Because the poles are bolted in, they can easily be replaced.

- Direct burial (also called embedded): Poles are buried directly in the ground. Installation is more straightforward than anchor-based and is less expensive. It eliminates the need for the anchor base and the extra labor involved in installing it. It also looks neater. Keep in mind that the pole needs to be taller to account for the pole section that will be buried in the ground. Direct burial poles are unsuitable for sandy areas or locations with loose soil. You could still use direct burial under these conditions, but you would need to increase the buried portion of the pole. Replacement of direct burial poles is costly and labor-intensive since the entire pole must be dug out.

LightMart Exclusively Offers an Additional Light Pole Option: EZ Sectional Light Poles

The EZ Sectional Light Pole is an innovative, patented square steel light pole with 4-foot segments for quick assembly at a job site. It drastically reduces handling and delivery issues associated with conventional single-shaft light poles without compromising its strength and EPA rating. Shipping is free and delivery can be made within a few days. When you combine shipping charges with pole costs, EZ Sectional Light Poles cost less than standard square steel light poles.

How Much Light Do I Need?

The amount of light you need depends on the size of the area you are illuminating and the brightness required. No matter what area you are trying to illuminate, LED lighting is now the clear lighting choice because of the many advances in LED technology. LED pole lights provide brighter light and are energy efficient with more significant energy savings.

Why LED?

- More Light: An LED light delivers much more light for the energy you’re using. For example, a 150-watt LED light provides the same amount of light as an old-style 400-watt metal halide light while using far less energy.

- Lumen Depreciation: An LED light has a low lumen depreciation, and it keeps 95% of its brightness after 10 years. The lights do not have to be replaced as often, meaning maintenance costs decrease.

- Directional Light: While most bulbs need a reflecting system to distribute light in different directions, LED light is directional, so it goes to the target area with no need for a reflecting system.

- Control Options: LED light allows end-users to have control options such as turning on and off as needed, dimming, changing colors, or Bluetooth controls.

What Wattage/Lumens Are Needed?

Most people look at wattage to decide how much light they need, but this is misleading. Wattage is not the only number you should consider; you must also consider lumens. Simply put, watts measure energy use while lumens measure brightness, so you need to look at both.

As an example, an old-style metal-halide 400-watt bulb produced about 21,000 lumens. Compare that to a 150-watt LED light which can produce the same number of lumens. If you only look at watts, you might think that the 150-watt LED light is not as bright as the 400-watt metal-halide, while in reality, the LED is just as bright while using far less energy while lasting a lot longer.

How Many Foot Candles Do I Need?

Foot candles is a term that the average person may have never heard of. Still, foot candles are the most important number to consider when determining the amount of light, you require to illuminate a given area. The number of foot candles you need depends on the lighting area you are trying to illuminate. Here are some examples of outdoor spaces and the number of foot-candles they typically need:

- Highways and parking lots: 1-2 foot candles

- General outdoor area: 2-4 foot candles

- The exterior of a building like a gas station or storage facility: 3-5 foot candles

- A highly lit commercial area like a car dealership: 10-20 foot candles

- A sports venue: 20-30 foot candles

Recommended Minimum Light Levels – Outdoors

Commercial light poles consist of some basic components aside from the pole itself, which can be customized to the needs of your lighting situation.

- Handhole covers allow electricians to access wiring for maintenance or replacement.

- Pole caps cover the top of the pole and are only necessary if the lights are on the side of the pole. Otherwise, a wide variety of brackets are available to attach additional lights to the pole, such as floodlights or other LED fixtures.

- Bracket types include bullhorns, to add 2-4 extra lights to the pole, right-angle brackets, which can also be mounted to walls, wraparound with 1-4 arms for round poles, and sports lighting brackets suitable for 2-6 heavy-duty sports light fixtures.

- Vibration dampeners minimize shaking. This is especially useful if installing a security camera on the light pole. Vibration dampeners also help absorb harmonic cycles in the post and increase the pole’s lifespan by minimizing the harmful effects of winds and breezes. Side brackets can be added for connecting additional lights to the pole.

- Electric outlets can be added to the pole to supply electricity for accessories such as Christmas lights, holiday decorations, and power accessories such as cameras.

- Banner holders can also be added to hang banners that advertise local events.

Need help with your next lighting project? Contact LightMart today!

Additional Resources

There is plenty to know about lighting and light poles. Installation and lighting standards are part of the knowledge base to help you make your lighting decisions.

Installation Resources

The two types of installations, anchor-based and direct burial, each has their place. Still, they also depend on your lighting purpose. In all cases, you want to make sure that the light poles are correctly and safely installed following all your town or municipality’s guidelines. It’s also important to know the wind rating for the area and the type of soil in which you will be installing the pole. If you are considering a do-it-yourself installation, it is recommended that you still seek professional advice from an engineer for expert guidance.

Light Pole Maintenance Resources

Although light poles can last a long time, they still require regular maintenance and inspection, just like any other structure. It’s important to properly maintain light poles to ensure safety, longevity, and aesthetics. See our Light Pole Maintenance Guide for more information.

Lighting Standards Resources

Commercial lighting standards are set by various national and international safety groups. Among them is the American Association of State Highway and Transportation Officials. Most transportation departments use AASHTO’s standards. In addition, the US Department of Transportation Federal Highway Administration sets standards for highway lighting on a national scale.

Why LightMart.com?

Lightmart.com has been serving its online retail customers with commercial lighting, light poles, and accessories since 1998. Our goal is to make life easier for lighting professionals by delivering quality products at significant savings. Our lighting engineers and technical experts are here to help you provide lighting solutions for your lighting project. Please contact us today with any questions or get a customized quote on larger projects.

Frequently Asked Questions

What types of commercial light poles are available?

By application:

- Stadium light poles

- Street light poles

- Parking lot light poles

- Outdoor area light poles

By installation type:

- Anchor Base

- Direct Burial

What materials are used to make commercial light poles?

Steel, aluminum, fiberglass, wood, and concrete. Each of them has pros and cons.

- Steel poles are strong and durable but conduct electricity and are prone to corrosion.

- Aluminum poles have a long life, are lightweight, and resistant to rust but are expensive and not fire-resistant.

- Fiberglass poles are extremely lightweight, resistant to rust and corrosion, and they don’t conduct electricity. However, they don’t last as long as aluminum poles and are very expensive.

- Wood light poles are inexpensive and easy to install. They don’t conduct electricity and are relatively lightweight. However, they are vulnerable to fire, infestation, and decay.

- Concrete light poles are resistant to fire, decay, and wind. They can be constructed locally and are inexpensive. However, they are not very aesthetically appealing, and they are difficult to install because they are extremely heavy.

How do I choose the right height for my commercial light poles?

This will be determined by its application. Common heights are as follows:

- Parking lots – 20-30 feet

- Street lights – 20-40 feet

- Sporting venues – 50-70 feet or more

It will also depend on the type of light fixture used and for what purpose. More information on selecting the proper height for light poles can be found here.

What kind of lighting fixtures can be used with commercial light poles?

Flood lights, area lights, and shoebox lights are the typical kinds of light fixtures used. LED lights are recommended due to their energy efficiency, long life, and light quality.

Are there any regulations I need to be aware of when installing commercial light poles?

There usually are and they are determined at the local level. This means that the location of the installation will have its own particular process for obtaining permits and meeting regulations. You will also need to know what the wiring and electrical requirements are for the location.

How do I maintain my commercial light poles?

This will depend on the material that the light pole is made from. For more information, see our Light Pole Maintenance Guide.