Light poles seem like they would be simple structures that would be easy to understand. That's not actually the case. They come in a wide variety of shapes, and sizes, and they have many types of applications. Here are some frequently asked questions that we get here at LightMart.

What are the different types of light poles offered by LightMart?

Materials

- Steel

- Aluminum

- Fiberglass

Installation Type

- Anchor Base

- Direct Burial (Embedded)

Pole Shape

- Round

- Round Tapered

- Square

- Square Tapered

Specialty Light Poles

- Security Camera

- Hurricane Resistant

- Wifi, Telecom, 5G Wireless

- Hinged

- High Mast

- Decorative

- Pole Kits

- Quick Ship

See our full selection here.

Why should I choose LightMart for my light pole needs?

- LightMart has the largest inventory of light poles in stock that can be quickly shipped to your project location.

- We have been in business since 1998 and have thousands of satisfied customers.

- Our products are made from high-quality materials and our manufacturing capabilities make us a factory direct provider of light poles and mounting brackets.

- We provide excellent customer service along with lighting and engineering expertise.

- We provide a wide range of customization options to fit any need.

What are the benefits of aluminum light poles?

Aluminum light poles are both strong and lightweight. Because they are lightweight, they are easier to install than heavier poles, such as steel, concrete, and wood.

They have the longest lifespan of any other type of light pole. One of the reasons for this is that they are resistant to corrosion and rust. This makes them ideal for use in coastal areas where salt water is a concern.

They also have an aesthetic appeal. You can choose a wide range of colors due to the anodization process.

How do steel light poles compare to aluminum?

Steel light poles are the most common type of light poles. They are less expensive and stronger than aluminum poles. Their strength allows them to handle high wind conditions and support multiple attached fixtures.

However, steel poles weigh more than aluminum poles. This is a consideration when it comes to installation.

Unlike aluminum poles, steel poles are susceptible to rust and corrosion. They do not have as long of a lifespan.

Why would I choose fiberglass light poles?

Fiberglass light poles are more lightweight than steel or aluminum poles which makes them easier to install. They are also stronger than aluminum and steel which makes them the most expensive type of light pole.

They have a longer lifespan than steel poles but shorter than aluminum.

Like aluminum poles, they are resistant to rust and corrosion, but they are also resistant to harmonic vibration.

How are LightMart poles rated for wind speed?

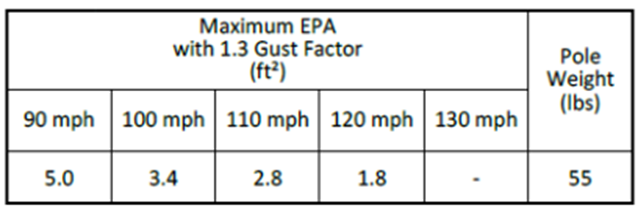

The specifications for our light poles include an EPA (Effective Projected Area) chart that tells you how much of a load they can safely handle based on the maximum possible wind speed for a given geographical area.

Each geographical area in the United States has a wind zone classification that is determined by the American Society of Engineers. Areas that experience high winds (such as on the coasts or in the mountains) will require stronger poles that can safely handle the load on top of them.

The number and types of fixtures (and their associated mounting equipment) that are placed on top of a pole will directly affect its ability to handle local wind conditions. Each item that is mounted on a light pole will have its own individual EPA rating value. Add them together and you can then cross-reference that value with the wind zone of your geographical area. This will tell you if the pole is suitable for your area. The weight and overall EPA mounted on any pole should not go above the pole’s maximum rating for the wind zone in which it is installed.

example EPA chart

Some orders qualify for free engineering calculations to ease the certification process with cities.

For more information, please see our article on EPA ratings .

What is the typical lifespan of a LightMart pole?

Before purchasing light poles, it’s important to know that protective coatings and finishes can be applied that will increase their lifespan.

Powder-coated and/or galvanized steel poles can withstand rust and corrosion much better than standard steel poles. Galvanized steel poles also provide protection for the interior of the pole.

Powder-coated or anodized aluminum light poles will provide additional protection from corrosion. Powder-coated aluminum poles have a hard finish that is tougher and longer lasting than conventional paint. Anodized aluminum poles are stronger and more corrosion-resistant than standard aluminum poles.

The typical lifespan for a light pole will depend on its material. They are as follows:

- Steel: 15-30 years.

- Fiberglass: 30-40 years

- Aluminum: 50+ years

What are the most common heights for LightMart poles?

10-30 feet is the common range for the light poles that we carry. We also carry sizes outside of this range (shorter or taller).

Common heights for some typical applications include:

- Parking lots: 20-30 feet

- Street lights: 30-40 feet

How do I install a LightMart light pole?

There are two main types of light pole installation: anchor-based and direct burial.

Direct burial light poles are inserted directly into the ground. There is no concrete base or anchor bolts required for this type of installation. Aluminum and fiberglass poles are used in this application because they will be partially underground and will not corrode or rust like steel poles.

Anchor base pole installations, as their name implies, require the pole to be anchored to a concrete footing with anchor bolts, nuts, and washers. The poles have a base plate that is welded to the pole and is used to attach the bolts to the concrete.

For more information, please see our article on light pole installation .

What maintenance is required for LightMart poles?

It’s essential to regularly inspect and maintain your light poles at least twice a year. It is key for the luminaire and light pole to maintain their appearance, long life, and safe operation.

- A visual inspection of the exterior pole shaft should be performed for areas of rust or corrosion. Look for dents or hints that the structural integrity is compromised. Ultrasonic thickness gauges can be used to help determine if there has been any corrosion in the interior of the pole and to measure the remaining pole wall thickness.

- Always make sure that covers for handholes, bases, and pole tops are firmly attached so that dust and moisture do not get inside.

- For anchor base poles, ensure that all anchor bolt nuts are in place and firmly tightened. This confirms that the base plate is properly secured to its foundation. Otherwise, the pole will begin to rock on its foundation during windy conditions. Loose anchor bolt nuts will also allow dust and moisture to collect under the base plate.

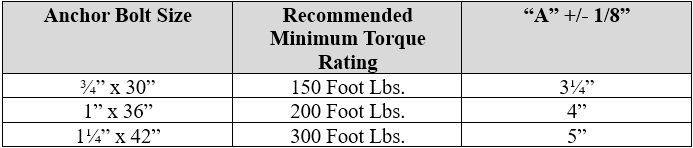

- It’s best to check and re-torque the anchor bolt nuts at least once a year, if necessary. You’ll need to know the recommended minimum torque rating for the bolts that you’re using so that they are not secured too loosely or too tightly. An anchor bolt projection chart can be used to find out what these values are. An example is shown below. “A” represents the measurement between the foundation and the top of the anchor bolt that is projected through the base plate.

example anchor

bolt projection chart

- For anchor base poles, inspect the concrete foundation for potential problems. Typical issues with concrete foundations include cracks, spalls (fragmenting), and leaning foundations.

- For steel poles that are not galvanized, condensation can enter the interior of the pole and cause rust and corrosion. This is an issue even for tightly sealed polls due to day/night temperature changes. If the base of the pole has been grouted (not recommended), you’ll need to have a weep hole so that water can drain to prevent it from building up.

- Ensure that any pole surface scratches are repainted/recoated so that the pole continues to be protected.

More information about light pole maintenance can be found here.

Can I customize my LightMart light pole?

Yes. LightMart has extensive manufacturing capabilities, and our products can be made to order. Our available customization options include color choices, custom pole height, and other accessories.

We have a process for requesting custom orders. Contact LightMart via phone or email. We will want to know the following information:

- What is the location of your project? We will need to know this to determine your area’s wind zone ratings.

- What is being mounted on top of your pole(s)? This includes light fixtures, security cameras, mounting hardware, etc.

- For poles that will have luminaires mounted on top, are there any foot candle requirements, light spill restrictions, and/or Dark Sky considerations for your area?

- Are there custom mounting bracket requirements?

- Is the project for new construction or are old poles being replaced? If the poles are being replaced, we’ll need to ensure that the anchor base fits properly (if applicable).

- What are the finish requirements? Will you need the poles to be painted, powder coated, anodized, or galvanized? This will depend on the material of the pole.

Lead time for custom projects will vary depending on the request. LightMart is a factory direct provider of light poles and mounting brackets. Depending on the requirements, lead times can be as short as a week or as long as 16 weeks.

- Short lead time examples include cutting poles for custom lengths or painting/powder coating a mounting bracket.

- A long lead time example would be for a 40 foot round tapered anodized aluminum pole.

Do you offer quick-ship light poles?

Yes. We have the largest inventory of light poles in stock. Our quick-ship light poles are a great time-saving option for your lighting projects.

How can I contact LightMart for more information or support?

Phone: (866) 407-4665

Email: help@lightmart.com

The LightMart.com website has a chat feature that will connect you with our sales team during business hours. The website also has a contact form that you can fill out.

Hours of operation: Monday-Friday, 8 AM-5 PM CST

David DeWald is the E-Commerce Marketing Specialist at LightMart. He has been working in the industrial and commercial lighting industry since 2013 and is based in the greater Chicago area. David specializes in digital product management, web content writing, and product marketing. He regularly publishes lighting industry-related articles on the LightMart blog. You can visit his LinkedIn profile here.