After a light pole is manufactured, certain finishes and treatments can be applied that will increase its lifespan and improve its appearance.

This article will explore the advanced technology behind protective light pole coatings, light pole finishes, and light pole treatments that enhance both the lifespan and aesthetics of light poles.

The Importance of Coatings and Finishes

Durability and Longevity

The life expectancy of a light pole depends on several factors:

- The environment in which it’s used: Harsh environments will require light poles that can better withstand the elements. Windy, rainy, and snowy climates can take a toll on a pole’s structural integrity. Coastal areas that experience sea salt spray are also considered harsh environments. This can lead to greater risks of rust, corrosion, and/or stress on the structure.

- Its application: Light poles that are installed in a quiet park can last a long time. Poles that are installed in industrial or marine environments are more likely to encounter harsh conditions. The same goes for installations in wastewater treatment plants, refineries, and even swimming pools (chlorine). In many cases, these areas have caustic chemicals that accelerate the corrosion process.

Special protective coatings and finishes help to extend the lifespan of a light pole by providing corrosion resistance and protecting it from environmental and/or application-related factors. The different types of materials used to manufacture light poles will factor into what types of finishes and coatings you will use.

Corroded light pole

Aesthetic Appeal

Special coatings and finishes contribute to the visual appeal of a light pole and can be customized to blend with different environments. This is especially important in public spaces where it’s preferable to have the poles match their surroundings.

Maintenance and Cost-Efficiency

Quality coatings and finishes reduce maintenance needs by increasing a pole’s lifespan. This, in turn, reduces operational costs which include the use of materials, labor, and equipment for upkeep.

Different Types of Coatings and Finishes

Powder Coating

Black powder coated finish

Powder coating is a kind of finish where electrically charged particles are baked onto the pole at a high temperature. It is utilized as a free-flowing, dry powder.

This is different from standard liquid paint. The powder coating process is usually applied electrostatically and then cured in high heat.

It is usually used to create a hard finish that is tougher and longer lasting than conventional paint.

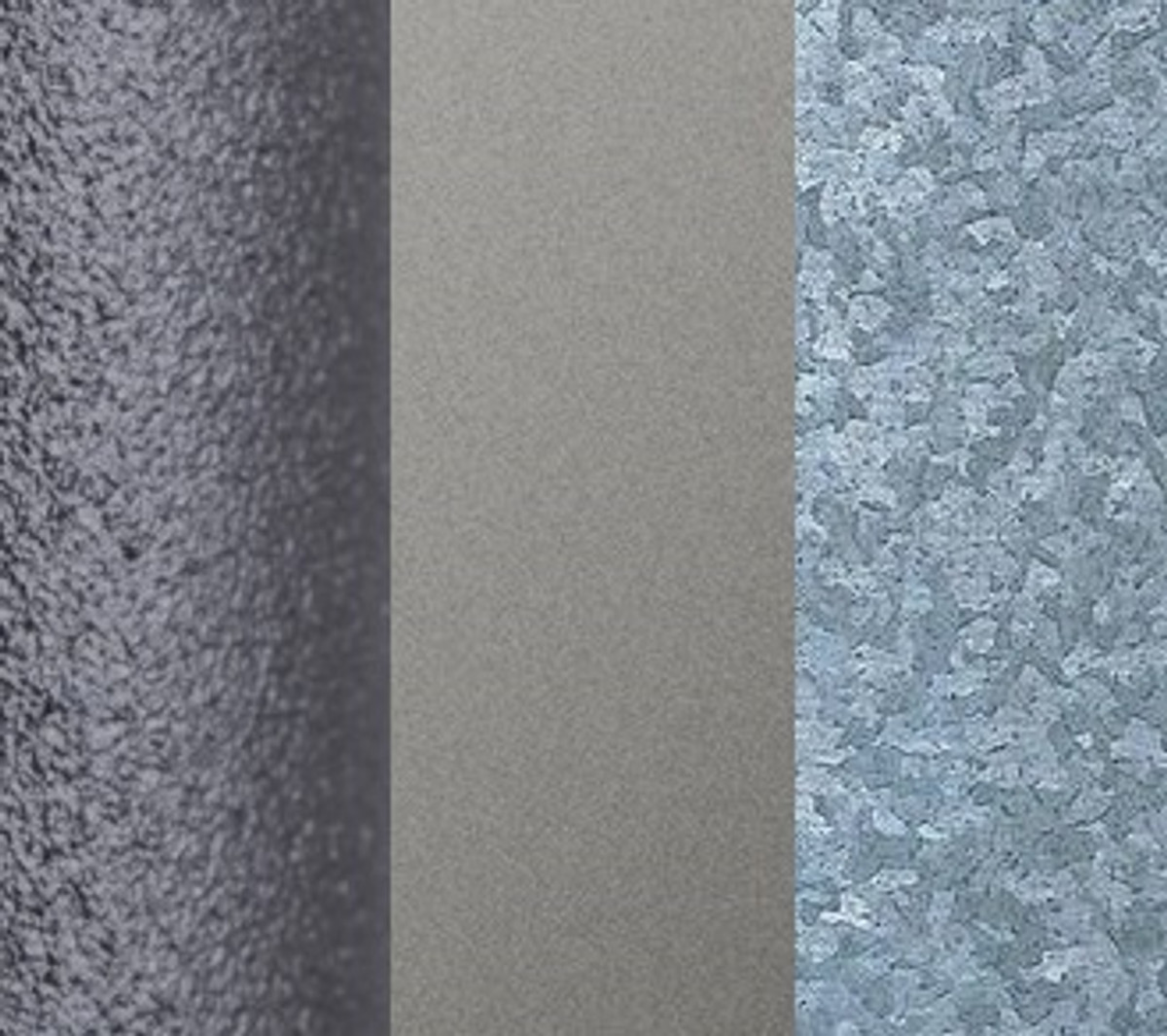

Galvanizing

Galvanized steel

Galvanizing is the process of dipping a steel pole into a zinc solution. Unlike other types of coatings, this solution coats the pole inside and out. This process is used to prevent corrosion.

A steel pole can be both galvanized and then powder coated afterward.

Anodizing

Anodized aluminum

Anodizing is an electrolytic process that gives aluminum poles a protective oxide coating that creates a durable, corrosion-resistant surface. This process will further strengthen the pole.

This process will change the color of the pole so you should select the color before the anodizing process. There are many color options.

The color change during the anodizing occurs due to the presence of other metals in the aluminum alloy. This will affect the aluminum oxide film that grows on the aluminum substrate. The alloying elements (like copper, zinc, magnesium, etc.) play a significant role in determining the color.

The Technology Behind Advanced Coatings

Nano-Coating Technology

Nano-Coating Technology provides superior protection against corrosion and weather elements.

During the nano-coating process, a surface layer is applied to the pole that will repel water, dirt, oil, and dry particles. Processes such as oxidation are halted and thus are resistant to corrosion. The pole’s surface also becomes harder and scratch-resistant.

Nanocoating bonds with a paint's clear coat through a transfer of particles, literally becoming part of the surface. In many cases, these bonds are so durable that the coating needs to be machine-buffed to be removed.

UV-Resistant Coatings

Light poles are constantly subjected to intense sunlight and damaging ultraviolet (UV) radiation from sunlight. UV-resistant coatings prevent color fading and material degradation.

Anti-Graffiti Coatings

Light pole with graffiti

There are two types of anti-graffiti coatings:

- Sacrificial coatings – These coatings are applied to a pole’s surface and are then removed when graffiti is present. Once the graffiti is removed, a new sacrificial coating can be re-applied.

- Permanent coatings – These coatings will stop graffiti from clinging to the surface altogether. These coatings form a protective surface that spray paint is unable to bond to. Once the surface has been spray painted, manufacturer-supplied cleaners or solvents are utilized to remove it. Cleaning up is usually as easy as performing regular maintenance. These coatings can last up to ten years.

Choosing the Right Finish for Different Environments

Coastal Areas

Coastal environments are particularly challenging for light poles, especially steel poles.

Major factors that contribute to accelerated corrosion rates include proximity to the shoreline and high humidity.

The salt in seawater is another major corrosion factor. Salt diffuses ions into water because it is an electrolyte. This intensifies the corrosion rate of metal. When combined with ocean air (which also contains salt), it causes the steel to corrode 10 times faster than inland air with normal humidity.

Galvanized steel poles can better resist corrosion in these environments, but anodized aluminum poles and fiberglass poles are recommended if they can safely handle their associated load in windy conditions.

Industrial Zones

In industrial environments, corrosive gases and uncontrolled humidity are the main causes of corrosion. Water condensation and corrosive gases like hydrogen oxides, sulfur oxides, chlorine, and ammonia can lead to the corrosion of electronic equipment, rusty bolts, and corroded parts.

Harsh industrial environments include water treatment plants, refineries, heavy manufacturing facilities, and steel mills. Due to these harsh and unusual environments, it is recommended that galvanized steel or anodized aluminum light poles be used.

Urban and Rural Settings

Light poles in urban environments tend to experience harsher conditions than those in rural settings. External impacts, graffiti, and urine are much more common issues that can contribute to undesirable appearances and corrosion.

LightMart’s Expertise in Light Pole Finishes

In-House Capabilities

LightMart’s has in-house capabilities when it comes to applying various coatings and finishes. Our state-of-the-art solutions ensure long-lasting durability and superior visual appeal for every light pole.

Customization Options

Among these capabilities are our in-house laser cleaning and powder coating applications. We can customize your light poles with a variety of colors to choose from. This ensures that you get poles that will match your specific aesthetic and functional requirements.

We also offer galvanized steel and anodized aluminum pole options.

Quality Assurance

At LightMart, we are committed to high-quality products and take pride in our work. Each light pole is meticulously finished to ensure durability and aesthetic appeal. Contact us today!

David DeWald is the E-Commerce Marketing Specialist at LightMart. He has been working in the industrial and commercial lighting industry since 2013 and is based in the greater Chicago area. David specializes in digital product management, web content writing, and product marketing. He regularly publishes lighting industry-related articles on the LightMart blog. You can visit his LinkedIn profile here.