Light poles are found everywhere, especially in outdoor public spaces. It’s impossible not to encounter them on our daily travels. This means that there is always a demand for them whether they are being used in new construction projects or replacing old ones.

The light pole manufacturing process depends on many factors. First, it depends on the type of material that is used to construct them. Second, it depends on the types of applications and installations that they will require.

This article is intended to offer insight into all the important aspects of the light pole production process.

Light Pole Materials

Not all light poles are made the same. Their composition will sometimes dictate what applications they will be suitable for. There are advantages and drawbacks for each type. These include cost, durability, and safety.

Steel

Steel is the most common material used for light poles. It is strong and durable. Steel poles can handle high winds and support multiple attached fixtures.

However, they conduct electricity and are susceptible to rust and corrosion.

Aluminum

Aluminum light poles are strong but are lightweight. They are resistant to corrosion and rust. Because of this, they can be installed near coastal areas where corrosion is a consideration.

They also have a long lifespan of 50+ years, which is longer than other types. This means that they don’t have to be replaced as often.

However, they are not as strong as steel and are more expensive. You’ll be paying a higher upfront cost for their longevity, but it will spread out over time due to their long lifespan. This return on investment is worth the cost if the poles can handle the load of the fixtures mounted to them.

Fiberglass (Composite)

Fiberglass light poles are lightweight yet strong and durable. They are non-conductive and resistant to corrosion, rust, and harmonic vibration.

Fiberglass poles last longer than steel but not as long as aluminum. Typically, around 20 to 30 years.

However, they are the most expensive type of light pole.

Wood/Concrete

Wood and concrete light poles are also common, but we will focus on steel, aluminum, and fiberglass poles for this discussion.

Light Pole Installation

There are two types of light pole installations; direct burial and anchor based.

Direct Burial (Embedded)

Direct Burial Light Pole

Direct burial light poles are inserted directly into the ground. There is no concrete base or anchor bolts required for this type of installation. Aluminum and fiberglass poles are used because they will be partially underground and will not corrode or rust like steel poles.

This type of installation is easier and less expensive than anchor based installation, but the shaft needs to be taller to account for the section that will be underground.

The drawback to direct burial installation when compared to anchor based is that it is not suitable for burial in loose sand or soil. Another drawback is that replacing the poles is more costly and time-consuming.

Anchor Based

Anchor Based Light Pole

Anchor base pole installations, as their name implies, require the pole to be anchored to a concrete footing with anchor bolts, nuts, and washers. The poles have a base plate that is welded to the pole and is used to attach the bolts to the concrete.

They are more costly and time-consuming to install than direct burial poles, but easier to replace and can withstand impacts from cars or trucks.

Light Pole Components

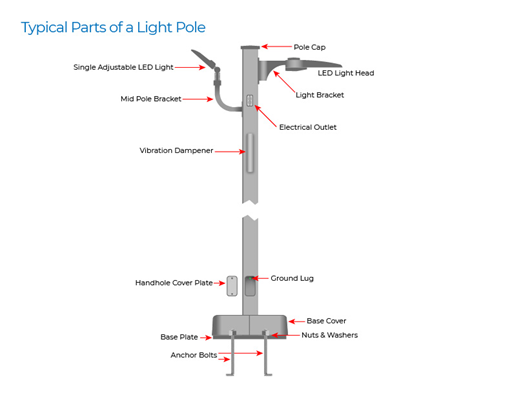

Before we discuss the manufacturing process of light poles, it’s important to understand their various components. They are not simply featureless shafts.

Diagram of Light Pole Components

Handhole/Cover (required for all light poles)

A handhole is an opening located towards the bottom of the pole shaft. It allows electricians access to internal wiring. A handhole cover is a plate that closes up the handhole and usually has a tamper-proof locking mechanism.

Conduit Hole (required for all light poles)

A conduit hole is an opening at or around the bottom of the pole shaft and is used to run electrical wiring inside the pole.

Base Covers and Plates

Base plates are welded to the bottom of steel and aluminum poles.

- For steel poles, the base plate is cut using a laser or plasma cutter. It can’t be cast.

- For aluminum poles, the base plate is cut, or it can be cast. If it is cast, you can have inventory in different sizes that are readily available when needed.

- Epoxy is used to attach base plates to fiberglass poles.

Aluminum Base Plates, Machined (l) and Cast (r)

Base covers (aka bolt covers) are used to cover the visible nuts and anchor bolts (if applicable). They are used as a safety measure and for a better appearance.

Light Pole Base Cover

Pole Caps

Pole caps cover the top of the pole if lights and/or brackets are not mounted there. They keep out rain and nesting birds. However, they don’t keep out condensation due to day/night temperature changes.

Light Pole Cap

Anchor Bolts, Nuts, and Washers

Anchor bolts, nuts, and washers are employed to fasten anchor based light poles to their concrete footing. Anchor bolt sizes will differ depending on wind conditions, pole height, soil composition, location, and weight on top of the pole.

Grounding Provision (Steel, Aluminum)

This is a safety requirement for all steel and aluminum poles to prevent electrocution. It is usually a lug nut inside the hand hole that is ground to a copper stake.

Grounding Provision for a Steel Pole (l) and Aluminum Pole (r)

Light Pole Manufacturing Process

The manufacturing process that light pole manufacturers use is different for each type of pole due to the difference in materials used. This section will provide you with a general overview of each type.

Steel

The manufacturing process for steel lighting poles is as follows:

- A flat steel sheet is cut to the desired width and length.

- The tube is formed by cold rolling or pressed on a brake. The cold rolling process is used for mass production but is not as flexible of a process as using a brake. The tube can be round- or square-shaped.

- Next, the hand hole and mounting holes are cut to specification. They are cut using a laser or plasma cutter.

- The base plate is then cut to specification and then slid onto the tube. A seam is welded on the top and bottom of the base plate.

- Finally, the pole is painted,

powder coated and/or galvanized.

Welded Base Plate and Cut Hand Hole on a Steel Pole

Aluminum

The manufacturing process for aluminum lighting poles is as follows:

- Aluminum light pole manufacturers use molten aluminum to form the poles. It is put into a mold that matches the specifications of the light pole shaft. Aluminum is very malleable which means that it can be formed into a wide variety of shapes and sizes by extrusion. The base plate can also be cast but there is an option to cut it and form it from a sheet.

- For anchor base poles, the base plate is then welded to the pole at the top and the bottom of the plate.

- The hand hole and mounting holes are then cut into the pole.

- Finally, there is an option to anodize the pole and base plate instead of powder coating.

Base Plate Welded to an Aluminum Pole

Fiberglass

Fiberglass poles have two primary components: fiberglass and resin. The manufacturing process for fiberglass lighting poles is as follows:

- Fiberglass cords are produced using fiberglass strands that are wound together. These cords are dipped into a polyester resin bath. They are then wrapped around a mandril.

- This tapered steel mandrel produces the shape of a light pole. The mandril pulls the fiberglass cords around itself by spinning. The angle and speed of the rotation are adjusted by an automated system. This is used to modify the strength of the pole.

- When the pole reaches the desired length and thickness, the mandril is pumped with steam to start the resin curing process. Within a few hours, the pole has cured and is ready to be pulled off the mandril.

- Next the pole is sanded to the desired finish and the excess material is cut off from the top and bottom of the pole.

- The fixture mounting holes, hand hole, and electrical conduit holes are then cut by an automated router.

- For anchor based poles, the base plate is attached using epoxy.

- Finally, the pole is powder coated or painted.

Light Pole Finishes and Treatments

After light poles are manufactured, certain finishes and treatments can be applied.

Powder coating (Steel and Aluminum)

Powder coating is a kind of finish where electrically charged particles are baked onto the pole at a high temperature. It is utilized as a free-flowing, dry powder.

This is different from standard liquid paint. Powder coating is usually applied electrostatically and then cured with ultraviolet light or under heat.

It is usually employed to create a hard finish that is tougher and longer lasting than conventional paint.

Galvanizing (Steel)

Galvanizing is the process of dipping the pole into a zinc solution, which coats the pole inside and out. This process is used to prevent corrosion.

A steel pole can be both powder coated and galvanized.

Anodizing (Aluminum)

Aluminum light poles are anodized, or powder coated.

Anodizing is an electrolytic process that gives the pole a protective oxide coating that creates a durable, corrosion-resistant surface. This process will further strengthen the pole.

This process will change the color of the pole so you should select the color before the anodizing process. There are many color options.

The color change during the anodizing occurs due to the presence of other metals in the aluminum alloy. This will affect the aluminum oxide film that grows on the aluminum substrate. The alloying elements (like copper, zinc, magnesium, etc.) play a significant role in determining the color.

LightMart’s In-House Manufacturing

LightMart has in-house, high quality manufacturing capabilities. This allows for faster distribution, better control over the production process, and the ability to produce quality products. It contributes to our ability to quickly ship the light poles that we keep in stock and offer express production light poles with shorter lead times.

Light Poles Ready to Ship

We have thousands of satisfied customers who rely on our expertise in the lighting industry. Our in-house staff has valuable experience when it comes to lighting layouts and electrical know-how. Contact us today!

David DeWald is the E-Commerce Marketing Specialist at LightMart. He has been working in the industrial and commercial lighting industry since 2013 and is based in the greater Chicago area. David specializes in digital product management, web content writing, and product marketing. He regularly publishes lighting industry-related articles on the LightMart blog. You can visit his LinkedIn profile here.